The Global Surge in Shipping Costs: Who’s Responsible & What to Expect?

The past few years have been tough for business owners due to different global scenarios. The traders are worried about the hurdle in global trade along with the rising shipping costs.

According to a CNBC report, “Shipping costs have skyrocketed as desperate companies wait weeks for containers and pay premium rates to get them, according to industry watchers.”

The total cut-down in the trade as well as rising shipping costs are major consequences of the pandemic 2020. And the business people are trying to figure the way out.

COVID-19 has wreaked economic havoc of epic proportions. In just a few months, every business on the planet, from small ventures to large enterprises, experienced unprecedented losses and disruptions that completely changed the game.

While we’ve managed to overcome some of them, there are a few challenges and effects that still persist. One of them is the rise in shipping costs.

Today, container shipping costs are at an all-time high.

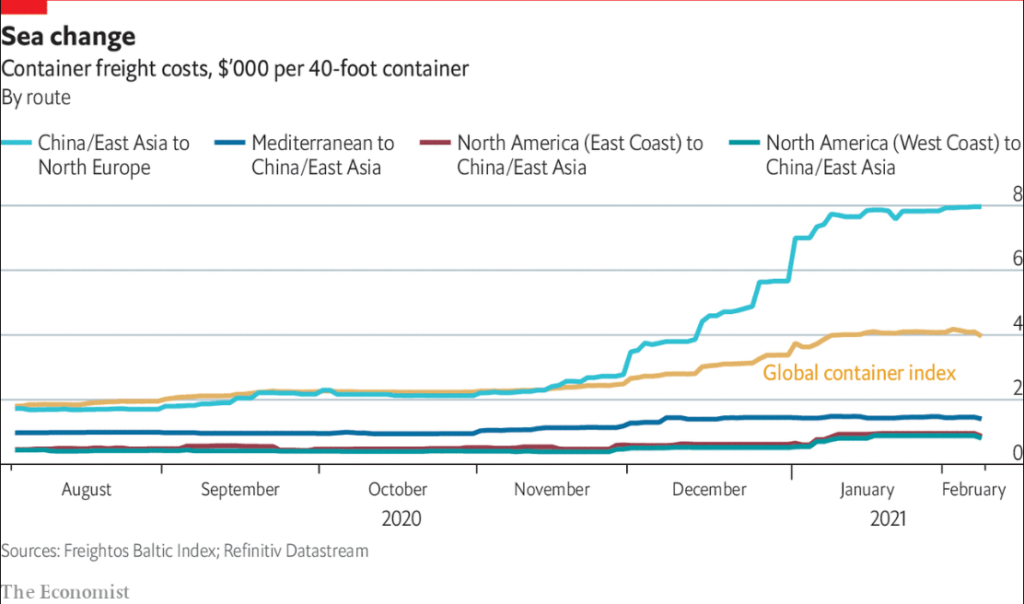

According to The Economist, the cost of shipping a container from Asia to the European region has increased from around $2,200 to a whopping $7,900.

Table of Contents

Rising International Shipping Costs

The current spike in the shipping rates is not coming down for at least a year. And as a result, the consumer would carry this burden. According to Bloomberg, The worldwide shipping rates have reached an unprecedented height. The rates of a container from China to the US or some European countries have reached the apex.

These surges influence everything from the supplier to the consumer. Most of the products reach us through shipping. The ultimate result would be a change in the behavior of the customer.

And apart from that, the whole process of buying and selling would suffer. The world witnessed how the Suez Canal incident affected the whole market. And that was just one week.

The real culprit of the current shipping cost increase in 2021 is still the deadly virus. Because after the pandemic the demand has increased rapidly by almost 100-200 percent after the end of the lockdown. But during the lockdown, the companies stopped supplying because the demands had dropped Do you wonder which countries have felt the impact of shipping cost increase in 2021?

The answer is the whole world. Because every country today depends on Trade. This means if there is positive news then all the world benefits. But, if there is bad news in trade then we all suffer together.

Businesses around the world – especially those that rely heavily on shipping for goods manufactured overseas, are feeling the pinch of these sky-high costs.

That, combined with jammed ports and shipment delays, has resulted in global disruption that isn’t expected to get resolved anytime soon.

We know that COVID-19 is the main culprit behind all of those problems.

However, what are the exact behavioral, business, and economic reasons that have contributed to this sudden surge in container shipping costs?

Furthermore, what does it all mean for shipping companies, brokers, and their clients (i.e. the businesses)?

In this article, we’ll discuss how these costs have changed over the past year, the potential reasons for the cost surge, as well as what high-volume export companies can expect in the near future.

Let’s get started.

The State of Global Shipping Costs [An Overview]

The global supply chains have never been this disrupted.

That’s not a guess or mere assumption based on the current situation.

Alarming statistics suggest that businesses are struggling to deliver customer satisfaction and keep other stakeholders happy.

According to the Institute for Supply Management (ISM), in the first 9 months of 2020, around 4,200 supply chain disruptions were reported – a 14% increase from the 3,700 disruptions reported in all of 2019.

Even a single break in the supply chain, no matter how small, has a ripple effect that can bring a business to its knees in a matter of days. One can only imagine the devastating effects of those huge numbers.

It all resulted from a series of lockdowns that were imposed throughout the world as precautionary measures against COVID-19. As a result of those lockdowns, many industries came to a halt, which, in turn, resulted in a lot of the shipments being called off in advance. This created massive problems for the carriers, brokers, and businesses alike.

When things got a little under control (at least in China), some Asian factories returned to routine manufacturing. Business owners that relied heavily on Chinese manufacturers took a sigh of relief.

However, keeping up with the massive demand of shipments became a nightmare, as ports became overwhelmed.

Coupled with the rising demand for alternative goods of the medical and protective variety, it increased the impact of the already unmet shipment demands.

This caused a global shortage of containers – an unprecedented challenge that drove shipping costs to an all-time high.

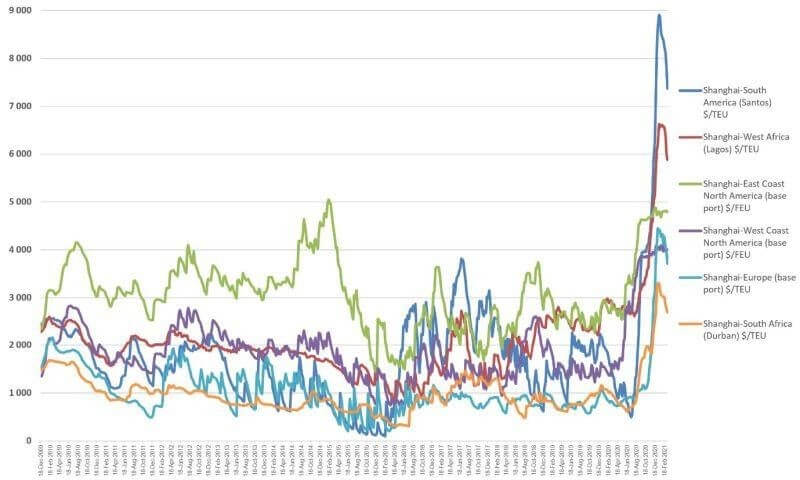

Here is a glimpse of how the shipping costs for different routes have changed:

As you can see – the longer the shipping routes, the more volatile and higher the cost of shipping.

Tracing the Hike in Shipping Costs to the Initial Hit

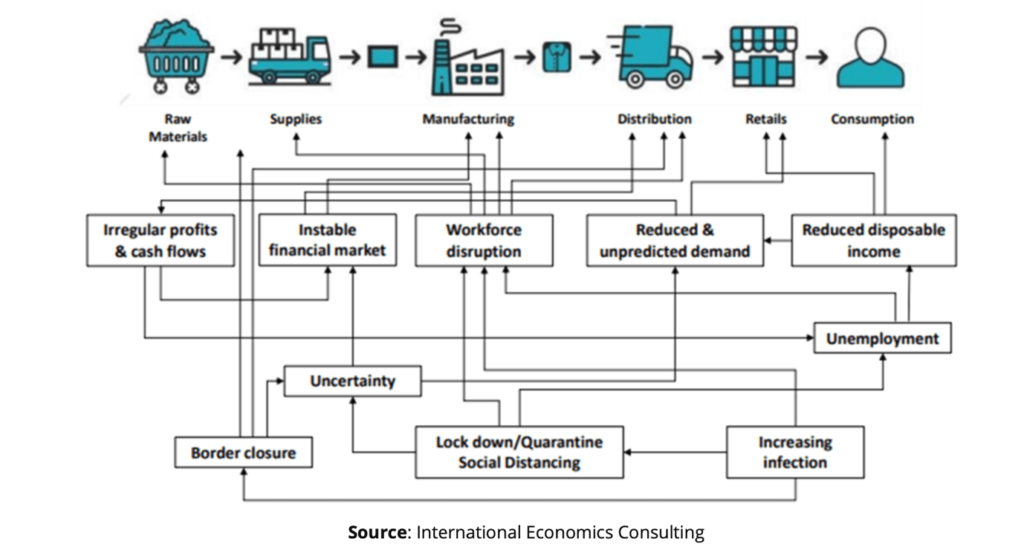

Saying that the pandemic affected supply chains would be an accurate way, to sum up, the situation. The figure below perfectly summarizes how disruptions in supply chains can have far-reaching effects, spilling over into areas such as demand and price spikes.

During the first worldwide lockdown in 2020, companies across the globe were required to issue a postponement on all shipping orders.

The ban on imports issued by various governments played a pivotal role in this reduction of demand.

The initial lockdown brought with it feelings of fear and uncertainty. The fall in demand in goods and cargo was a prominent symptom of this fear.

Governments were suddenly expected to direct all their resources to house infected patients and provide the necessary resources and equipment to protect the general population. With uncertainty, danger, and warnings from WHO, governments all over the world had to balance out trade with the economy.

Making a Tough Choice

To avoid a surge in cases, government bodies restricted the process of goods crossing into country borders. Fear and panic regarding the virus became relative to the influx of shipping containers from across the globe, as they were seen to bring the virus and its detrimental effects with it.

When these strict safety measures were put in place, land logistics became particularly dysfunctional, at least during the first lockdown.

On the airborne freight front – airlines suspended up to 90% of their passenger routes. This resulted in the lowest air freight capacity drop seen in three years.

Governmental restrictions that aimed to slow down the spread of the outbreak undoubtedly led to logistical impairments worldwide. A study on mobility found that as a result of the pandemic, overall mobility dropped by 76%, especially those by road (93%). UNCTAD has compiled some insightful statistics regarding the impact of the initial pandemic hit, on logistics as a whole.

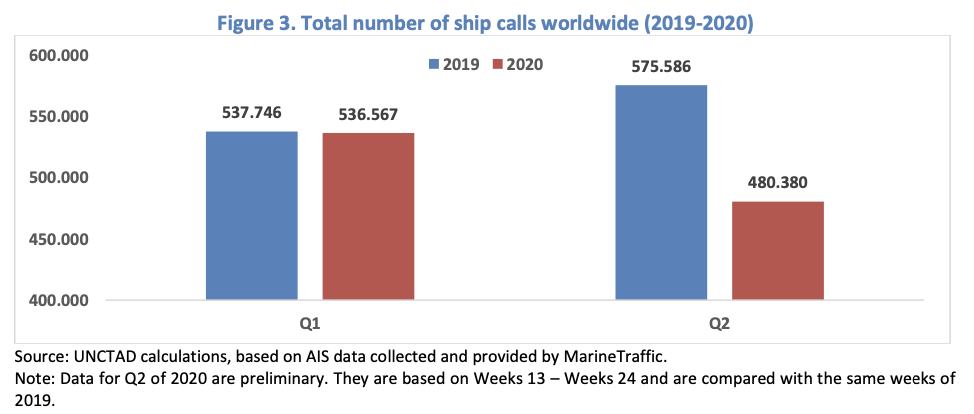

This figure displays that in the first 24 weeks of 2020, global Port calls for maritime freight fell by 8.7%, while a dramatic plunge in these rates occurred in the following quarter, with a reduction of 17.5% as compared to 2019’s second quarter.

This massive reduction reflects the course of action governments began to take in order to prevent the outbreak from wreaking more havoc in the country.

These government measures include, but are not limited to national lockdowns, work suspensions, and placing trade embargoes on other countries.

The Economic Impact on the Logistics Sector

Around 80% of global trade volume is supported by commercial shipping.

Considering that, it’s no surprise that even the slightest disturbance in the commercial shipping ecosystem can drive up prices, among other Econo-political effects.

According to Malik Moin, former chairman of the Pakistan International Freight Forwarders Association, ‘freight charges for cargo in a 20-foot container arriving from China to Pakistan (countries right next to each other) increased by $2000-3000, compared to $700 in June 2020’.

Before the pandemic struck, the cost of 1 CBM (1m3) looked something like this:

- Rail Freight – USD 100-140

- Sea Freight – USD 35-70

- Air Freight – USD 5-12 (for 1 kg)

After the pandemic, for reasons mentioned later on in the article, some examples of freight rates between China and the USA/Europe show the shocking change in freight rates:

- Sea freight going from Shanghai to Hamburg (9.6CBM) costs $1,890 (the original cost for this would be $336-672)

- Rail freight from Foshan to Warsaw (carrying 21.29CBM) costs $4,800 (the original cost for this would be $2,129-2,980)

- Air freight from Yiwu to New Jersey (carrying 60kg) costs $1,190 (the original cost for this would be $300-720)

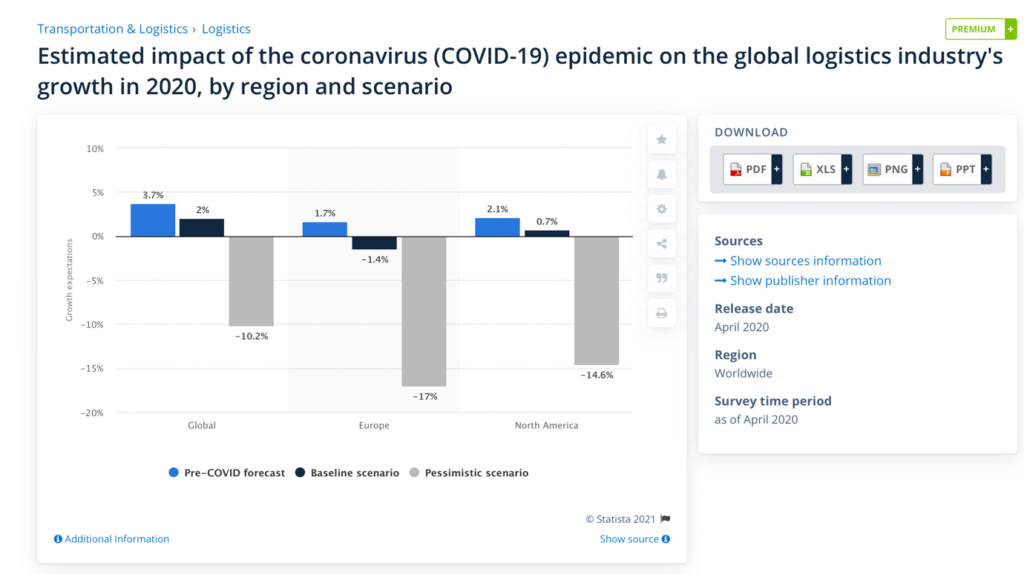

These figures show how significant the shift in cost was, and how it had the power to (financially and economically disrupt businesses of all scales. The following figures provided by Statista further break down how the outbreak and its consequences have placed a strain on virtually every sector within the logistics industry.

Based on these statistics, the economic activity of the logistics sector can be down by 10.2% worldwide. That is NOT a small number.

Upon the initial hit of the virus, seeing the way the world responded, transport and trade sector expected a 41-50% reduction in revenues within Africa.

Overall, the shipping industry estimated their volumes falling a significant amount (between 20-25%).

A Shift in Cargo Types

Economy and finance were not the only fronts that saw major change during and after the initial wave.

There was also a natural shift in demand from everyday goods such as clothing, electronics, and automobiles, to goods that determined likelihood of survival for patients.

Almost every country around the world, especially the most populated ones, saw a massive uptick in demand for medical supplies, personal protective equipment (PPE), as well as food and beverage.

Demand for the last one was especially high when lockdown was imposed, as it created feelings of fear, uncertainty and anxiety.

What Do the Numbers Say?

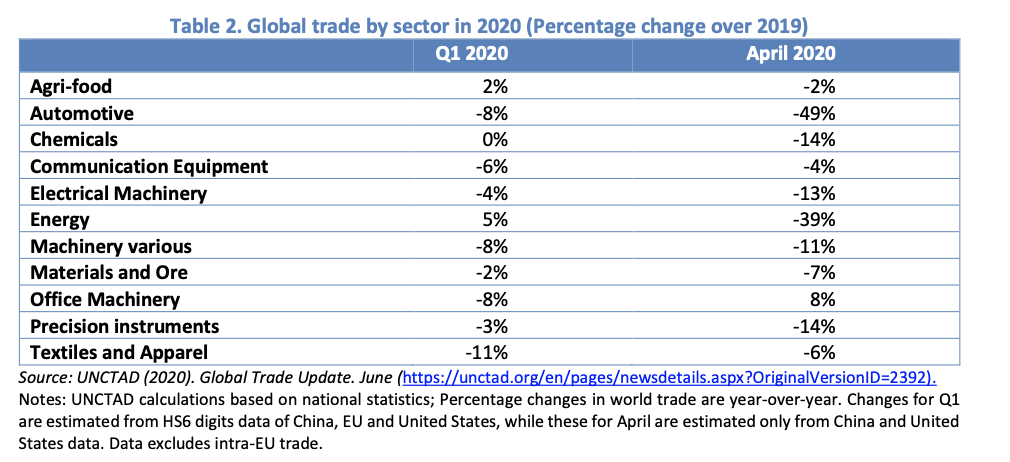

UNCTAD compiled some statistics comparing the state of the trade sector with regards to standard goods in the first quarter and April of 2020, to that of 2019.

This figure displays how there was a noticeable turn in demand from goods that were not immediately required or considered a necessity. There was still a general fall in demand owing to the economic consequences of the virus.

Emergency gear such as PPE, surgical masks, N95 respirators, hygiene-related products like sanitizers and soaps (currently, the Covid-19 vaccines) all saw a huge rise in demand. This was unprecedented and industries were not prepared to produce or send out products in such volumes.

Supply could not keep up with demand initially, as consumer preferences for goods instantly shifted, leading to a spike in shipping costs across the globe.

While agri-food is a necessity, it can be seen that its export/import through the first few months of 2020 was lower than in 2019, despite entering lockdown.

The economic effects that the initial hit of the virus caused have led to problems for economies even in the food and beverage side of things. It’s important to note that this is the one industry that was seen as indispensable, and untouched by economic collapse in various parts of the world.

As the Economic Times mentions, the higher costs for transporting US grain and soybean in countries across the Pacific pose threats in terms of increased food prices in Asia.

This effect goes both ways. Thailand, Vietnam, and Cambodia also struggled in their exports of rice, as they were unable to secure containers to send their shipments of rice (and other grains) to North America and various other regions.

What is Responsible for Increased Shipping Costs?

All things considered, the increase in shipping costs threw a wrench in the plans of many businesses around the globe.

Interestingly, we’ve barely scratched the surface of the potential culprits that led to this gradual rise in shipping costs. Having said that, there are some areas where we can place our magnifying glass in an attempt to investigate where our suspects likely emerged from:

Container Shortage

The shipping container, according to The Economic Times, is the ‘workhorse of globalization’. When the workhorse loses power, the world is sure to be affected by it. Therefore, the curious case of container shortage is a story worth looking into first.

As the world entered a complete lockdown within the first quarter of 2020, existing containers with supplies ready to be shipped out were left stranded in their departure ports. In simple words – there aren’t enough containers to go around!

This has continued well into 2021, contributing to a container shortage that the world has never experienced before.

The continuous peak of global shipping costs can mainly be attributed to this unusual shortage of containers.

What Contributed to This Shortage of Containers?

The pandemic played a pivotal role in promoting eCommerce.

Quarantined at their homes, many people had no choice but to make their day-to-day purchases online.

However, the online shopping didn’t stop at the daily groceries.

During this time, people stuck in their homes unleashed a flurry of orders from companies who primarily sourced their products from Chinese manufacturers.

This massive demand stands in stark contrast with the scarce supply of shipping containers. Following from this basic problem of demand and supply, economics states that the massive gap between demand and supply is bridged with price.

This price equalizer is essentially the surge in shipping costs and freight rates.

Apart from that, compliance to the government(s)-imposed standard operating procedures (SOPs) that require working-from-home and self-isolating policies, has resulted in a massive cutback in terms of available personnel.

Basically, container shortage is coupled with labor shortage, which means more delays and setbacks in the loading/unloading of cargo, adding to the complexities of cargo shipping.

And, as demand continues in this pressing situation, prices will naturally increase.

Combining these circumstances with the instance of ports operating in a dysfunctional manner (a massive cargo traffic jam, which shows no signs of clearing up soon), we can see how container shortages have led to a hike in shipping costs.

Government Embargo

In 2020, many countries formerly engaged in trade, imposed trade embargoes to avoid further spread of an already deadly virus. These countries had already entered a state of shock as massive portions of the population fell victim to the virus, maxing out their healthcare resources.

While the virus spared no one, economies including those of the United States, China, Italy, Spain, Germany, Brazil, India, and Iran, were most affected by the virus.

These are places where cases reached as high as six-digit figures.

In the U.S., for example, former President Donald Trump announced a restriction on travel and an embargo on goods from China in late January 2020, and the same to Italy six weeks later.

These were initially seen as controversial decisions, but other countries soon followed this restriction to avoid increasing the number of infections.

South Africa was also quick to enforce a travel restriction 10 days after a confirmed patient returned from Italy.

These economies are powerhouses of production and manufacturing.

Consider China, a country previously known as the epicenter of manufacturing, housing more than 200 of the Fortune Global 500 Firms. It’s now known as the origin of the Covid-19 virus. Its logistical disruption sent ripple effects over the world’s economy.

According to UNICEF, suppliers in China make up the largest share of the market.

Considering the Wuhan province as the virus’ origin, the country was embargoed by others across the world, resulting in a massive fall in supply.

Since China is a prime manufacturer, the initial hit of Covid-19 resulted in a backlog of cargo in its ports, followed by a shortage of truck drivers and ocean carriers. This affected industries such as automobiles, pharmaceuticals, electronics, and consumer goods.

Change in Shipping Priorities

The increasing demand of protective gear and instruments in the face of COVID-19 pandemic was another notable factor in driving up shipping prices. This gear includes face masks, N95 respirators, and medical clothing most commonly utilized by medical staff manning the frontlines in hospital settings.

Affected countries also partook in stockpiling strategies, which further increased demand of the already crippled supply of such protective gear.

In the first quarter of 2020 alone, the UN had distributed over 6.4 million gloves, 1.8 million surgical masks and 1 million gowns, according to UNICEF.

The current developments in R&D mean that Covid-19 vaccines are now ready for distribution.

With massive pressure and overburdening of road and ocean freight, industries such as technology, automobile, and medical devices have been making use of air freight as the primary shipping channel.

Furthermore, the demand for air freight is growing alongside China starting its manufacturing industry again. However, rates have spiked to 27%, according to easyship.com.

To keep up with this demand, air carriers such as American Airlines and British Airways are using passenger planes for cargo.

China also began using maritime freight to ship out protective personal equipment (PPE), sending it out across the world. Chinese factories made an explosive comeback within the second half of 2020, trying to keep up with increasing demand.

It was the deployment of these necessities that revived trade and imports/exports around the world.

Governments realized that the virus could not be waited out, and that proactive steps had to be taken.

What began with just PPE being shipped out, continued into general consumer goods.

Now, the same is being done for the Coronavirus vaccine. These are being shipped from their countries of origin to countries across the world, mainly via air freight.

Dysfunctional Ports

Amidst all the panic in shipping, there has emerged a problem that nobody could have predicted (or at least, wasn’t completely prepared for).

The amount of cargo traffic that has backlogged ports is immense, and it currently shows no signs of clearing up in 2021. In fact, at this pace, the backlog may even continue well into 2022.

This traffic exists in all spheres – air, sea, and road. The choke has also contributed significantly in driving up the shipping costs.

Bob Biesterfeld, CEO of C.H. Robinson WorldWide Inc., says that air freight prices have doubled since the past year and that long-haul trucking rates are likely to enter the double-digits.

The extensive traffic has led to dysfunction of the ports, which has resulted in delays of their departures and in the loading and unloading process. Pandemic restrictions have also cut down on the labor force, adding to the delays in cargo handling.

The increased traffic and the lack of labor means limited resources are available for one of the most in-demand services as of now – shipping.

These shipping bottlenecks, that have been amplified by the dysfunction at ports with regards to space, workforce, procedures, and efficiency, are all contributors to the sky-high prices that shipping companies are now demanding.

Other Potential Reasons

The economic crisis may not be the only factor for higher shipping rates.

The overall reduction in demand and supply of transportation services has led to a decreased supply of maritime owners, with ships being docked.

When reduced demand and supply go hand in hand in a certain industry, prices tend to rise.

It is also possible that shipping companies are unable to generate stable profits despite route closure.

While shipping costs may have increased, it is entirely possible that some shipping companies may be re-investing the same amount that they receive from their services.

The Suez Canal Incident

Rare accidents can also be a factor that explains how shipping prices are spiking up.

Seaborne vessels stuck at sea, like the Suez Canal incident, is a recent example we can elaborate on.

Sometimes it’s just accidents and mishaps. The most recent one involved the Ever Given container ship getting wedged and blocking the Suez Canal on March 23rd, 2021.

With a length of 400m and weighing over 200,000 tons, this Taiwanese ship is one of the largest container vessels in the world.

The initial blame was placed on the exceptional wind speeds, which the Suez Canal Authorities (SCA) dismissed. Constant maneuvers and attempts by tugboats finally freed the ship six days after blockage, during which a traffic of 369 ships had accumulated in the Suez.

Seeing that around 12% of global trade, one million barrels of oil, and 8% of LNG pass through the canal daily, SCA chairman Osama Rabie estimated a loss of $14-15 million, each day. This blockage did not only affect the global shipping industry but innumerable businesses.

Rare incidents like these in any industry can drive up shipping prices inexplicably high, as statistics show.

The main problem? It’s difficult to predict and therefore prepare for such incidents until they happen.

However, the Suez Canal crisis has certainly raised some questions about some practices in the shipping industry (more specifically, about the size of the vessels).

Many experts believe that carriers would be better off with smaller vessels, as they pose smaller margins of error. This, in turn, may also drive down overall shipping costs.

Shipping Costs in the Near Future: What to Expect in 2021 and Beyond

As we have entered 2021 with a ray of hope, hearing of successful vaccine trials and then witnessing them being distributed for public administration, we are beginning to expect everything to go back to normal.

However, exactly when they go back to normal is an entirely different matter. Experts believe that we still have a long way to go.

Just like the uncertainty associated with the COVID-19 virus and how far its effects will slow down our recovery, can we say the same about the logistics and shipping industry?

There is no dispute over the fact that the pandemic has instilled a (somewhat) permanent change in consumer buying habits.

According to Forbes, there has been an approximate 12.2% increase in the number of senior shoppers (aged 65 and above) who shop online. After spending months solely dependent on the web, from workout machines to home-office furniture, this is a habit that won’t be disappearing anytime soon.

Apart from demand, there are predictions that shortages of shipping containers and the issue of cargo traffic will persist well into this year, if not also spilling over into 2022.

Given this reasoning, the past year saw an exponential rise in shipping costs as a by-product to the shock caused by the pandemic. Such an increase in costs, while a product of our behaviors, is not sustainable.

According to FitchRatings, spot container freights will carry on strong into 2021, upholding their contract rates for the year. However, current rates are unsustainable, as the industry may be vulnerable to ‘rate volatility, and the ‘risks of weak economic recovery and trade protectionism’.

As of 2021, these high shipping rates may persist, but will neutralize in the ‘medium term’.

What Does it Entail?

Xu Changtai, chief marketing strategist of Morgan asset Management in Asia, predicts that the economic state of 2021 will largely remain under the influence of the events of 2020.

This implies that the logistics industry will also be operating similarly.

He says, “The first half of 2021 can be regarded as the starting age of the new economic cycle, that is, the early growth stage.”

ZeyMarine also states that owing to the fact that enough cargo vessels will not be coming into the market in 2021 freight rates may persist throughout the year.

The Economic Times also informs how experts forecast a scarcity of containers throughout 2021, as China will continuously struggle to keep up with the demand of these container vessels.

These forecasts are not arbitrary. These are being calculated keeping current situations in mind.

Peter Baum’s company uses Chinese and Southeast Asian factories to make products such as umbrellas, cotton bags and ceramics. Until June of 2020, he was paying around $2500 to ship a 40-foot container to California.

As of January 2021, the company had to pay $67,000, ‘the highest freight rate that I have seen in 45 years in the business’, according to Baum.

There seems to be a general understanding that 2021 will likely see the spill-over effects of 2020, i.e. shipping costs and high freight rates will persist as the problems that caused this are not in a position to be solved before the end of this year.

Beyond 2021, in the years to come, there are many general expectations forecasting a wave of stability in the massively unsustainable costs. As the world begins its recovery, shipping costs will slowly go back to normal.

Conclusion

Given the unpredictable state of the pandemic and the level of its economic impact on various countries, it is difficult to say assuredly how things pan out in the future, as the world attempts to recover from the after-effects of the turbulence the year 2020 brought for it.

Having said that, and as shown in some of the statistics earlier, we have proven time and again our resilience and our ability to cope in the face of emergencies.

In the wake of economic upheaval, as businesses are slowly beginning to resume their operations, and the population is starting to adapt to the new normal that has been thrust upon them, there is hope.

There is some reassurance from the global analyst community that while the aftershocks of 2020 will likely linger all throughout 2021, and possibly also the years to come, this situation of a global surge in shipping costs is likely to be temporary, given its unsustainable nature.

Perhaps this surge in shipping costs was what was needed to bring a perspective shift in the industry of logistics and shipping.

Perhaps this is the sign we’ve needed to implement digitization and a hands-free experience in this process, or to refine supply-chain process in trade.

Only time will tell if any of our predictions, expectations, and hopes will come to fruition.